"The implementation process was so streamlined. It concerned me years ago when I first started looking at it because I had to hire a 3rd party custom integrator and then rely on my limited internal resources to help execute on the implementation. There's none of that with RoboJob-USA. That was the struggle years ago when the standard CNC automation products did not exist in the market. One of the main reasons why I chose RoboJob-USA was because the implementation was clean and so streamlined."

-Jim Carr - CARR Machine

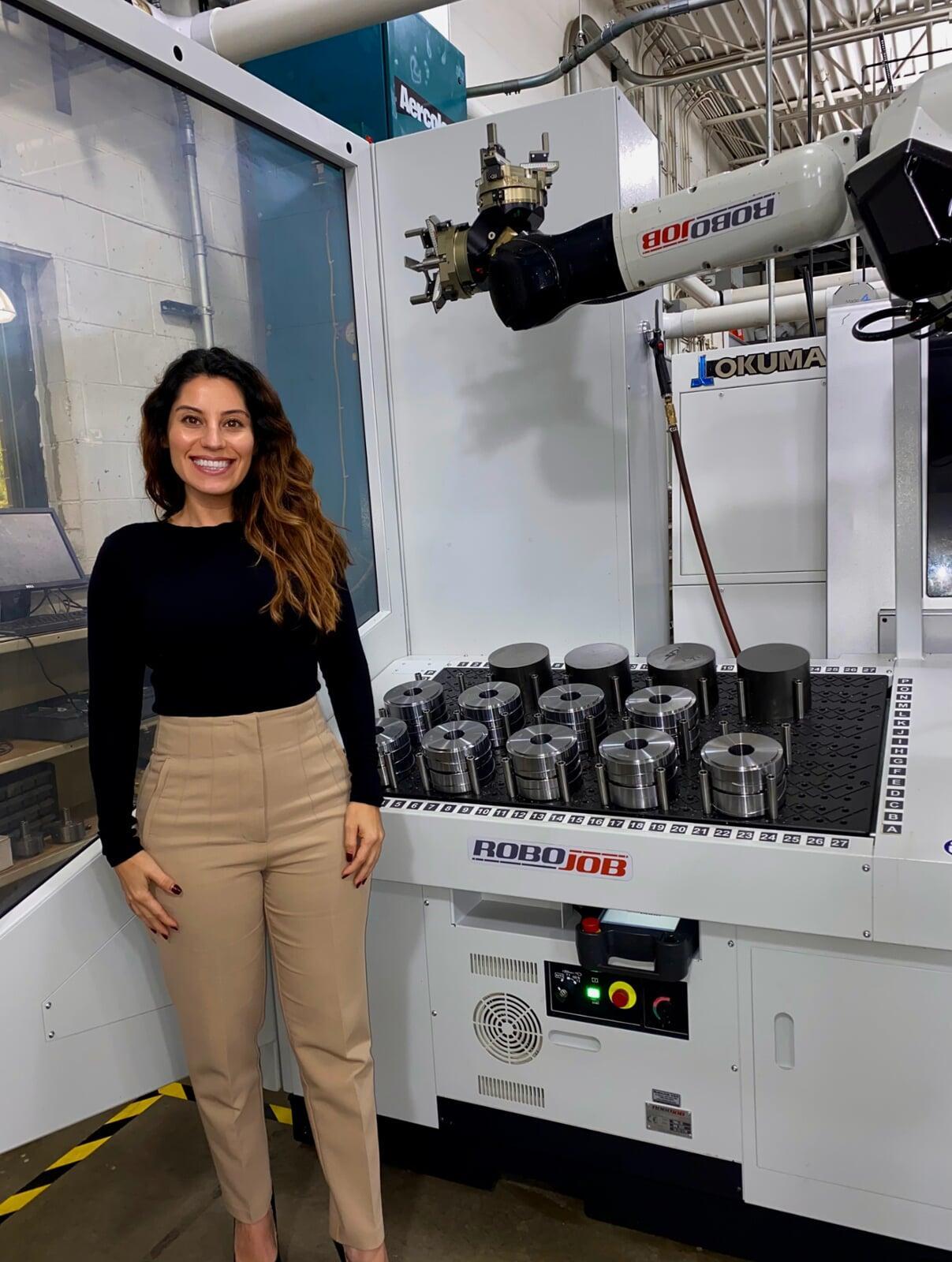

"I think there's this huge stigma that automation is cumbersome, it takes a lot of time to program, it takes a lot of time to set up, that if you're not doing tens of thousands of parts, it's not useful. Now that we have it and have been using it, the programing is super easy, the set-up is super easy. We can do it in minutes and so that’s great when you have a lot of different parts that you must run. "

-Nicole Wolter - HM Manufacturing

"The simplicity of the entire package is what stands out to me. The software is great! The fact that I can program it is incredible because I don’t have a machining or automation background. Product quality, versatility, and even the price point – it’s very affordable. Regarding the support, you just don’t see what RoboJob-USA is offering anymore. The “no fuss” support, as I call it. You just take care of stuff."

-Mike Payne - Hill Manufacturing

"Just research the CNC automation market and consider the product and the support after the sale. We bought a RoboJob and a Halter at the same time and put the two head-to-head. Our biggest decision factor in choosing is more about the service and support than the actual equipment, so it's really who we're working with, and I think you guys did better than the competition, so that's why we chose RoboJob-USA. The equipment was very similar, but the after-the-sale support was far superior."

-Scott Harrington - NTI

"We were completely sold on the ease of the user interface. We go in there, put the size of the material and it automatically tells the operator what to do with the set-up. Everyone on our team here feared this before with the Cobots and it is now not a concern whatsoever. Since we've implemented RoboJob products, everyone around Kris Dee is trying to figure out which parts can be automated with a RoboJob next."

-Jeff Majewski - Kris Dee

"Almost all our nine machines are fully automated. I’d like to add that the owner of the company points to this every time when we're looking at new CNC equipment, we're not looking at the machine anymore, we're looking at the automation. The machine is a machine, but the robot is what's going to make that machine most productive. Automation is more important than the machine in our opinion. That's how I feel about it. It's unreal the improved efficiencies that we've gained here. We put out almost triple the parts without adding anybody, and we even removed a CNC from the shop floor and gained more space to operate."